Our solutions:

Examples of treated products: Water, fruit juices, etc …

STORAGE TANKS

Product description:

- Storage of liquid products

- Tanks with capacities of up to 300,000 litres are manufactured in our workshops

- Operating conditions in accordance with customers’ needs: Atmospheric, ultra-clean, and sterile conditions

- Agitation defined depending on the product’s rheological characteristics (viscosity, density) in order to ensure it is kept homogeneous in the tank

FILTERS

For many years, GOAVEC Engineering has been implementing full turnkey water treatment units and makes a commitment regarding the end physical and chemical result.

Product description:

- Water physical and chemical treatment filters implementing various types of media depending on the treatments to be carried out in order to achieve the criteria set by the various European Directives, in compliance with the Ministry of Health

- Tanks with capacities of up to 40,000 litres are manufactured in our workshops

- Operating conditions depending on the treatment needs: Atmospheric, pressure level

- Specific equipment items developed for the use of media

Examples of treated products: Spring water, sparkling mineral water, etc …

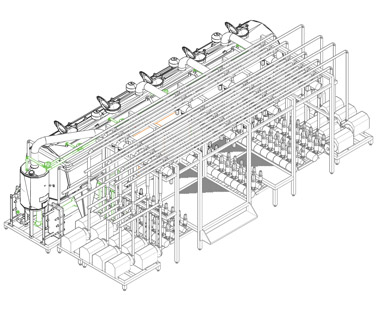

MONOBLOCK AUTOMATIC CLEANING UNIT

Product description:

- The NEP single-piece unit consists of a horizontal tank with several compartments:

- 1 to 5 compartments

- 1 to 6 lines

- Compartment capacity of up to 5,000 litres

- Steam or electric heating of the solutions

- It is assembled and cabled in our workshops. Hydraulic and electrical tests validate its smooth running before delivery

- A Siemens, Schneider, or Rockwell programmable automatic controller ensures the staging operations as well as the various cleaning cycles

- An operator terminal enables management and parameterisation of the washing cycles

- CNAO: A computer-assisted learning design utility ensures the NEP unit’s greater flexibility and limits the discharges from an environmental perspective

WATER TURNKEY PROCESS INSTALLATIONS

- Pumping

- Storage of still waters

- Physical and chemical treatments

- Regeneration systems

- Neutralisation of regeneration discharges

- Washing and disinfecting the whole installation

- Possible flavouring

- Artificial carbonation or recarbonation of spring using natural gas

- Automation and supervision of the unit

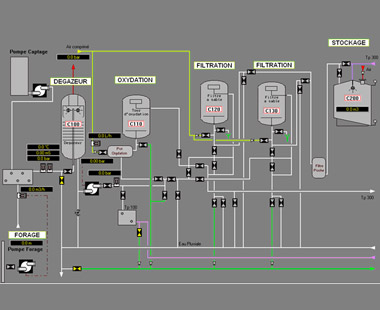

HYDROTHERAPY TURNKEY PROCESS INSTALLATION

GOAVEC AND HYDROTHERAPY

From the borehole to physical and chemical treatments and through to distribution to the treatment stations.

- Gas extraction

- Iron removal

- Manganese extraction

- Arsenic reduction

- Fluorine extraction

- Sulphur removal

- Ozonation

- Filtration

- Regeneration

- Discharges neutralisation

- Scale removal

- Chlorination

- Disinfection

- UV

Disinfection and scale removal by a washing unit sized to match your processes.

Electrical and automatic control systems adapted to the site.The compliance of its experience as an assembly manufacturer for the agrofood, cosmetics and pharmaceuticals industries combined with its skills in terms of water treatments make Goavec a recognised actor in the hydrotherapy sector in France.

BEVERAGES TURNKEY PROCESS INSTALLATION

Goavec Engineering designs and executes:

- Pilot installations

- Storage and distribution of raw materials

- Pasteurisation / Sterilisation skids

- Production installations (flavoured water, fruit juice, dissolved sugar, flavours dosing, incorporating citric acid, decarbonation, etc…)

- Fixed and mobile CIP / SIP stations

- Storage and distribution of finished products up to the packaging machines

- The electrical and automatic controller architectures

Examples of products processed by our teams:

- Spring waters

- Flavoured waters

- Sparkling mineral waters

- Sugar syrup

- Fruit juices

- Spirits

- Alcohols

- etc …