Our solutions:

Examples of treated products: Fruit juices, oils, chocolate, …

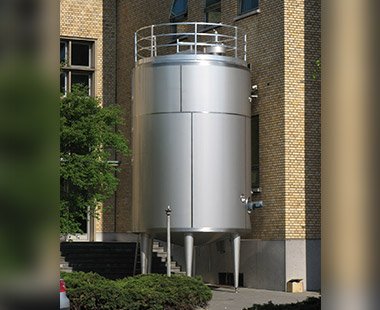

Storage tanks

Product description:

- Storage of liquid or paste-like products

- Tanks with capacities of up to 300,000 litres manufactured in our workshops

- Service conditions according to customers’ needs: Atmospheric, ultra-clean and sterile conditions

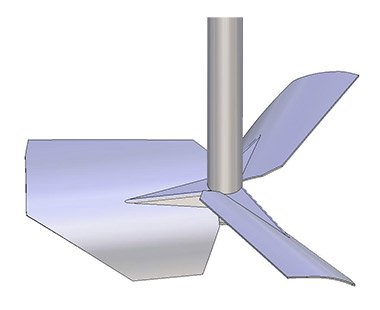

- Agitation defined depending on the product’s rheological characteristics (viscosity, density) in order to ensure it is kept homogeneous in the tank

Application example:

A specific study carried out in collaboration with the manufacturers of raw materials for suitable treatment of chocolate lines.

STERILE TANKS

GOAVEC Engineering has been manufacturing sterile tanks for 30 years and developed its first tanks in collaboration with dairy-sector industrial operators (UHT milk). The technicians of our customer service will support you during requalification of your apparatuses.

Product description:

- Aseptic storage of finished products before sterile packaging

- Tanks with capacities of up to 60,000 litres manufactured in our workshops

- Operating conditions in accordance with customers’ needs: steam/vacuum 3 bar sterilisation

- Boilerworks designed and manufactured in accordance with Pressurised Equipment Directives

- Optional agitation, defined in accordance with the product characteristics (viscosity, density). Shaft passage design in order to limit any risks of bacteriological contaminations (double seals with steam barriers)

- Specific equipment items developed for cleanability as well as guaranteeing being free from contamination

Examples of treated products: UHT milk, starter cultures, …

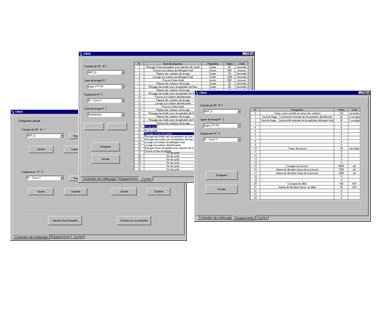

MONOBLOCK AUTOMATIC CLEANING UNIT

Product description:

- The NEP monoblock unit consists of a horizontal tank with several compartments:

- 1 to 5 compartments

- 1 to 6 lines

- Compartment capacity of up to 5,000 litres

- Steam or electric heating of the solutions

- It is assembled and cabled in our workshops. Hydraulic and electrical tests validate its smooth running before delivery

- A Siemens, Schneider, or Rockwell programmable automatic controller ensures the staging operations as well as the various cleaning cycles

- An operator terminal enables management and parameterisation of the washing cycles

- CNAO: A computer-assisted learning design utility ensures the NEP unit’s greater flexibility and limits the discharges from an environmental perspective

ROBOSTAR

Product description:

Robostar is a multi-purpose machine dedicated to industries using batch processes.

- Standard capacities: 60 l, 200 l, 500 l and 1,000 l

- Operating conditions: 0.49 bar (Pressurised Equipment Directive variant: 3 bar)/vacuum

- Various sorts of agitation are proposed depending on the characteristics desired in terms of mixing (keeping the substance homogeneous, liquid or paste-like mixes, heat exchange, emulsion, crushing, cuttering, dispersion of powders, etc.), and depending on the rheologies of the products to be treated (viscosity, density)

- Process functions available:

- Direct/indirect heating

- Cooling

- Pressurisation

- Vacuum

- Cleaning in place

- Sterilisation in place

- Manually-operated or automated process (operating procedure)

Examples of treated products: chocolat, ganache, pâte d’amande, sauces, plats cuisinés, …

Examples of treated products: Ready-cooked meals, sauces, sugared fruits, pet foods, purées, bolognaise, white sauce, …

VERTICAL COOKERS

Product description:

- A cooking tank enabling direct or indirect heat treatment to be carried out whilst maintaining the integrity of the treated product (pieces, fragile products)

- Tanks with capacities of up to 20,000 litres are manufactured in our workshops

- Operating conditions in accordance with customers’ needs: Atmospheric, vacuum, ultra-clean and sterile conditions

- Agitation defined depending on the product’s rheological characteristics. Frequently you will come across a scraping anchor, a counter-rotating fitting, or quick crushing and dispersal tools

- Specific equipment items developed for heating, cleanability, inserting raw materials, and work station ergonomics

COOKING BALLS

Product description:

- A spherical cooking tank facilitating mixing and enabling direct or indirect heat treatment to be ensured whilst maintaining the integrity of the treated product (pieces, fragile products)

- Tanks with capacities of up to 2,000 litres are manufactured in our workshops

- Operating conditions in accordance with customers’ needs: Atmospheric, vacuum, ultra-clean or sterile conditions

- Agitation defined depending on the product’s rheological characteristics. Frequently you will come across a scraping anchor, a counter-rotating fitting, or quick crushing, dispersal and cuttering tools, as well as whisks and beaters

- Specific equipment items developed for heating, cleanability, inserting raw materials, and work station ergonomics

Examples of treated products: Ready-cooked meals, sauces, pasta, …

Examples of treated products: Ready-cooked meals, sauces, white sauce with or without pieces, …

COOLERS

Product description:

- A cooling tank enabling quick cooling via optimised air conditioning connected to thermal fluids whilst at the same time maintaining the integrity of the treated product (pieces, fragile products)

- Tanks with capacities of up to 20,000 litres are manufactured in our workshops

- Operating conditions in accordance with customers’ needs: Atmospheric, vacuum, and ultra-clean conditions

- Agitation defined depending on the product’s rheological characteristics. Frequently you will come across a scraping anchor and a counter-rotating fitting

- Specific equipment items developed for heating, cleanability, inserting raw materials, and work station ergonomics

TILTING COOKERS

The tilting cooker is a multi-purpose tool dedicated to the agrofood industries. It treats liquid and paste-like products which can reach high viscosity levels, multiple rheology levels, and may feature pieces in them (pieces, vegetables, meats, etc.)

Product description:

- Scraping agitation specifically designed to ensure regular movement of the product

- Optimal thermal performance characteristics linked to the air conditioning technologies used

- The finished products are poured out by tipping them into European-style bins

- Numerous options are available depending on the needs to be handled

- Tanks with capacities of 600 litres/1,200 litres are manufactured in our workshops

Examples of treated products: Ready-cooked meals, sauces, white sauce with or without pieces, …

Examples of treated products: vegetable fats, butter, chocolates, paraffin, …

MELTING VESSELS

GOAVEC Engineering designs and implements various melting vessel technologies depending on the raw materials to be melted (pastilles, tablets, blocks).

Product description:

- An atmospheric melting machine enabling the whole mass to be brought to melting temperature depending on the melting rate desired

- 2 main technologies are offered:

- An anchor melting machine

- A melting vessel with a melting table (for blocks)

- Tanks with capacities of up to 10,000 litres are manufactured in our workshops

- Optimal air conditioning in order to ensure high yields. Fluids used: Hot water, steam, thermal oil

- Specific standardised equipment items for managing the controlled hot water system and work station ergonomics (loading blocks)

HORIZONTAL COOKERS

Product description:

- A cooking tank enabling direct or indirect heat treatment to be ensured whilst maintaining the integrity of the treated product (pieces, fragile products)

- Tanks with capacities of up to 2,000 effective litres are manufactured in our workshops

- Operating conditions in accordance with customers’ needs: Vacuum, pressure (Pressurised Equipment Directive)

- Scraping horizontal agitation with or without heat exchange, enabling mixing operations involving pieces to be carried out as well as heat treatment

- Full heat exchange surface in order to ensure high production outputs

- Specific equipment items developed for heating and cleanability.

Examples of treated products: Rice, sugared fruits, vegetables, …

Bactosas

The purpose of this equipment item, which was patented in 1988, is to separate the production clean zone from the equipment grey zone

It has become an alternative to white rooms in the agrofood, cosmetics and pharmaceuticals industries

It guarantees that food safety is maintained in the production zone. It also facilitates maintenance actions in the grey zone without interactions with the production zone

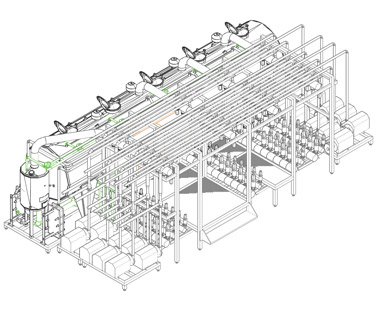

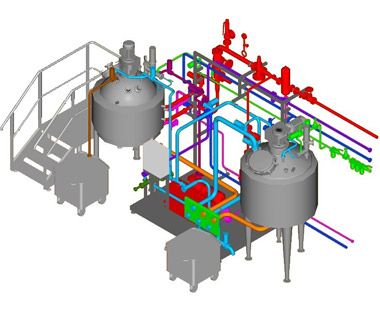

TURNKEY PROCESS INSTALLATION

Goavec Engineering designs and executes:

- Pilot installations

- Fixed and mobile CIP/SIP stations

- Storage and distribution of raw materials

- Pasteurisation / sterilisation skids

- Production installations (yoghurt, butter, cream, starter cultures, soft cheese, crystallisation installation, whey treatment, etc…) linked to our processes tanks

- Storage and distribution of finished products up to the packaging machines

- The electrical and automatic controller architectures

Examples of products processed by our teams:

- Chocolate

- Oils

- Vegetable fats

- Glucose

- Sauces

- White sauce

- Bolognaise

- Tomatoes

- Cream

- Garnishes

- Vegetables

- Fruits

- Compote

- Ready-cooked meals

- etc…