Our solutions:

Examples of treated products: Cream, shampoo, lotions, …

STORAGE TANKS

Product description:

- Storage of liquid or paste-like products

- Tanks with capacities of up to 300,000 litres are manufactured in our workshops

- Operating conditions in accordance with customers’ needs: Atmospheric, ultra-clean, and sterile conditions

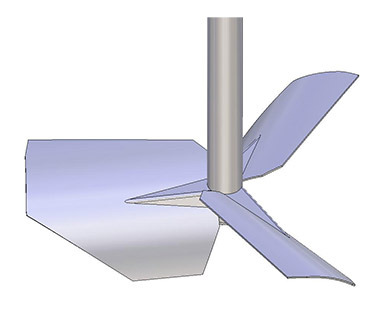

- Agitation defined depending on the product’s rheological characteristics (viscosity, density) in order to ensure it is kept homogeneous in the tank

Robostar

Product description:

Robostar is a multi-purpose machine dedicated to industries using batch processes.

- Standard capacities: 60 l, 200 l, 500 l and 1,000 l

- Operating conditions: 0.49 bar (Pressurised Equipment Directive variant: 3 bar)/vacuum

- Various sorts of agitation are proposed depending on the characteristics desired in terms of mixing (keeping the substance homogeneous, liquid or paste-like mixes, heat exchange, emulsion, grinding, cuttering, dispersion of powders, etc.) and depending on the rheologies of the products to be treated (viscosity, density)

- Process functions available:

- Direct/indirect heating

- Cooling

- Pressurisation

- Vacuum

- Cleaning in place

- Sterilisation in place

- Manually-operated or automated process (acceptance procedures)

Examples of treated products : Creams, ointments, etc …

Examples of treated products : Shampoos, creams, ointments, lotions, milk, mascara, foundation, …

MANUFACTURING TANKS

Product description:

GOAVEC Engineering manufacturing reactors equipped with triple-movement agitation mechanisms enable the manufacturing of emulsions and paste-like products in compliance with the latest GMP recommendations in force (NF EN ISO 22716).

- Tanks with capacities normally ranging up to 20,000 litres are manufactured in our workshops

- Operating conditions: Vacuum, pressure of 3 bar (Pressurised Equipment Directive)

- Triple-movement agitation including counter-rotating hanging agitation combined with a latest-generation emulsifying unit in the bottom of the tank: The tool’s pumping and shear rate vary depending on the desired particle size

- Specific equipment items developed for inserting raw materials, the cleanability of the equipment, and ATEX classifications

- Air conditioning designed and executed in order to ensure high yields. The usual thermal fluids: Steam, chilled water, thermal oil

PRE-MIXING EQUIPMENT/MELTING UNITS

Product description:

The pre-mixing equipment and melting units enable the manufacturing of aqueous and fatty phases that comply with the parameters of the final formula made in the manufacturing tank.

- The ancillary tanks and melting units comply with the latest GMP recommendations in force (NF-EN ISO 22716)

- The ancillary units are frequently equipped with the same types of agitation mechanisms as the manufacturing vats (triple movement agitation), thereby enabling the manufacturing of smaller batches.The melting units will be designed depending on the products to be melted and mixed. Priority will be given to thermal performance characteristics

- Units with capacities normally ranging up to 10,000 litres are manufactured in our workshops

- Operating conditions according to customers’ needs: Atmospheric, pressure level (Pressurised Equipment Directive), vacuum

- Agitation mechanisms defined on a case-by-case basis depending on the rheological characteristics of the products to be treated. GOAVEC Engineering offers a wide range of mobile agitation units in order to respond to customer specifications

- Specific equipment items developed for inserting raw materials, the cleanability of the equipment, and ATEX classifications

- Air conditioning designed and executed in order to ensure high yields. The usual thermal fluids: Steam, chilled water, thermal oil

Examples of treated products: Shampoos, creams, ointments, lotions, milk, mascara, foundation, …

BACTOSAS

(white zone/technical grey zone separation)

The purpose of this equipment item, which was patented in 1988, is to separate the production clean zone (inspection area) from the equipment grey zone. This reduces white zones and facilitates access to technical equipment in the grey (technical) zone.

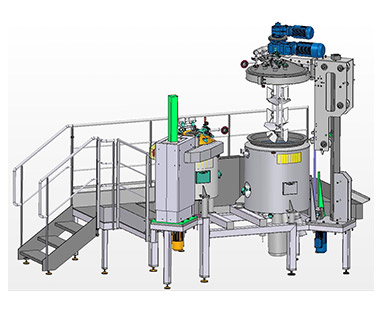

TURNKEY PROCESS INSTALLATION AND PLATFORMS

Goavec Engineering designs and executes:

- Mobile tanks with instrumentation

- Pilot skids

- Stand-alone melting units

- Storage and distribution of bulk raw materials

- Automated production platforms

- Storage and distribution of finished and semi-worked products up to packaging

- CIP / SIP station

- Systems for softened water, purified water and water for injection

- Clean fluids distribution

- The electrical and automatic controller architectures

Examples of products processed by our teams:

- Lotions

- Skin milks

- Creams, emulsions

- Ointments

- Toothpaste

- Shampoos, conditioners

- Sunblock products

- Hair removal creams

- Mascara

- Foundation

- Perfumes